|

| Although I wrote this article for builders of the John Smith

organs, it became apparent to me that commercial organ builders may also

be interested in this double-acting bellows system, as it offers several

advantages over the conventional system, and is much easier to make.

I have never seen this idea before, but I do not claim it to be original.

In the hundreds of years that organs have been built, I am quite sure that

somebody else must have thought of this before me! I would be interested

to learn if anybody has ever seen this idea before. I did present my

idea in the Busker Organ Forum in 2016, inviting readers to let me know if

they had seen it before, and nobody has yet said that they have. One

of the leading UK experts and collector in the mechanical organ field has

also told me that he has never seen the idea before. He thought it

might not work - but it does work, perfectly!

Full instructions and photos for making one of these pump units

for a John Smith Busker or Universal Organ are given in

this article. |

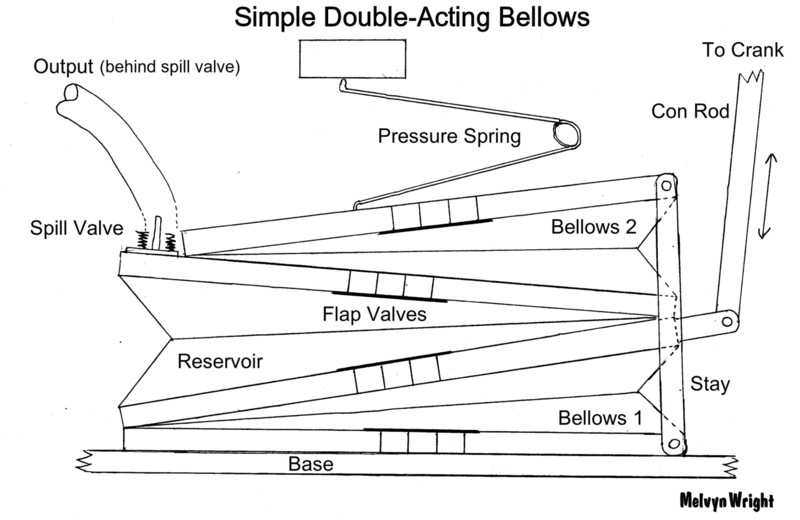

Simple Double-Acting

Bellows

To make the organs easy to build, one compromise that John Smith had to make

in his organ plans was to use single-acting bellows. Commercial organs almost

always use double-acting bellows which supply air on both the down stroke

and the up stroke. John got around this by using two bellows working in

opposition, which has the same effect; but each bellows is only half the

width, so the whole system only supplies half the wind of a conventional

system.

Double-acting bellows are quite difficult to make for the amateur builder.

There are complicated blocks of wood to machine, and internal wind channels

to drill, and the geometry is more complex. But after much thought, I have

come up with a double-acting bellows system which can be built just as easily

as the John Smith single-acting one. My system will supply more than twice

as much wind as the John Smith system, and it only needs a single crank to

operate it.

My idea is similar to the conventional double-acting system which has two

bellows one above the other, and a reservoir mounted on the top. The

trouble with this is that the bottom bellows has no direct access to the

reservoir. This has to be provided by a complicated angled hinge block with

internal wind channels and a very restricted flap valve. Also, the

top bellows is sandwiched between the bottom bellows and the reservoir, and

has no direct access to the atmosphere, except by further internal channels

that come out of the side of the bellows.

I solved both of these problems by removing the reservoir from the top, and

placing it in between the two bellows! Now, both bellows have direct

access to the reservoir and also to the atmosphere. The internal wind

channels are no longer necessary, neither is the complicated hinge block.

The wind is generated not by moving the bellows, but by moving the

reservoir up and down between the bellows! See the diagram below for

a sketch of the idea:

|

|

On paper this idea seems to be bonkers and would never work (which could

be why it's not been done before?) but it works perfectly. The hinge end

of the reservoir is at the opposite end from the bellows hinges, so that

as the reservoir opens and closes it does not affect the opening and closing

of the bellows. You can see from the diagram that when the reservoir

expands, all it does is to push the hinge of the top bellows up a bit, which

does not affect the operation at all. Similarly, the hinge of the reservoir

moves up and down with the crankshaft, but this doesn't affect the operation

either!

The bellows and reservoir are all made using the same simple techniques as

used in the plans. They are just mounted in a different position. They

can all be made individually and then glued (or screwed) together, simplifying

design, construction, covering, and maintenance considerably.

Only a single crank is required, which makes the crankshaft considerably

easier to make than the double crankshaft in the Busker, or the triple crankshaft

in the Universal.

Because of the various fitments required on the reservoir (the output connection,

the relief valve, and the pressure spring) it is necessary for the top bellows

to be about 2" shorter than the reservoir. But in the conventional

double-acting system both bellows have to be 3 or 4" shorter than

the reservoir because of the bulky hinge block carrying the air passages.

The pressure spring presents no problem as it simply presses down on the

top bellows! The top bellows board does not move up and down, so the

effect is just the same as if it was pressing down directly on the reservoir.

Because of the slight sideways movement of the reservoir, the spill

valve is best operated by a length of cord connected to the bottom reservoir

board.

The two stays must be at the corners, otherwise when the reservoir opens

it will restrict the movement of the bellows. These are only under tension,

so do not need to be very strong. Thick wire could be used.

As well as being much easier to make, the possible advantages of my system

over the conventional system are:

1) Both bellows have direct access to the reservoir and also to the atmosphere,

so no complicated internal airways and hinge blocks are needed, and the air

movement is less restricted.

2) There is no restriction on the size of the flap valves.

3) Will supply more wind, due to the absence of the hinge block.

4) All three bellows assemblies can be built entirely separately and then

glued (or screwed) together, or the whole thing can be made as a single unit

by the more experienced builder.

5) All of the three bellows assemblies have simple geometry, with both boards

being of equal length and converging to a point. This makes measuring and

glueing the bellows cloth/leather much easier.

6) The height and capacity of the unit is adjustable, simply by lengthening

or shortening the stays. So for example if it is found to supply more than

enough wind, the height can be lowered by shortening the stays, to take up

less space in the organ (and vice versa). Of course, the crank throw

would also need to be changed to suit.

7) With no complicated airways, and simple bellows construction, I believe

the potential for air leaks is much less. Each of the three bellows units

can be tested separately before assembly.

Full instructions and photos for making one of these pump units for a

John Smith Busker or Universal Organ are given in this

article. |

|

|

Three examples that I knocked up in a day!

The big one is intended for a John Smith Universal Organ |

Some Considerations

The only disadvantage with this system, that I can see, is that the reservoir

moves backwards and forwards slightly during operation. I thought this

may cause several problems, but fortunately this has turned out not to be

the case. There were three possible problems that I was initially concerned

about: The spill valve operation, the output connection, and the pressure

spring.

The spill valve is easily solved by operating it with a length of cord connected

to the bottom of the reservoir. The sideways movement of the reservoir

top board then has no effect. Internal spill valves are often operated

in this way, so this is nothing new.

The output connection on many organs is by a flexible tube to the reservoir

top board, which moves up and down. This does not cause any problems.

On this system, the movement is mostly sideways and I wouldn't expect

it to cause any problems either. If there are any problems, it would be a

simple matter to re-arrange the output tube to minimise the flexing. For

instance it could be arranged to form a loop so that the loop absorbed any

movement. An alternative would be to take the output from the bottom

reservoir board, as this just tilts a bit. This would, of course, mean

shortening the bottom bellows as well as the top one.

I thought the greatest problem would be with the pressure spring, and obtaining

a constant pressure when the bottom of the spring is moving backwards and

forwards. But in the examples I have built, this has not turned out

to be a problem. The pressure is stable, with the simple pressure spring

shown in the diagram. There is a possibilty that the pressure could vary

though, so here are a few simple ways this could be rectified:

Turn the spring in the diagram through 90 degrees so that it comes out towards

you. The sideways movement then has no effect. In fact the pressure

spring shown in the diagram would seem to be in the worst possible position,

as it tilts up and down with the movement of the reservoir; but it still

works well!

Move the top of the spring further up and away from the reservoir. This reduces

the angle of movement.

Use two pressure springs, one facing left and the other facing right. Any

sideways movement will then be cancelled out.

Use tension springs between the top and bottom reservoir boards. They

won't even know that the reservoir is moving!

Use a weight!

It would appear that the varying air pressure inside the top bellows would

press up and down on the reservoir top board, and affect the pressure in

the reservoir, but this does not happen in the examples I have made. The

pressure is rock-steady and there is no rhythmic pulsing at all. See

the video for proof. But it is important to make sure that there is

minimum resistance to the air movement in and out of the top bellows. So

I would recommend that the area of the flap valve holes in each board is

at least 1/30th of the area of that board. This is a generally accepted

formula anyway. For example, if the moving bellows boards are 400 x

200mm then the total area of the valve holes in that board shoud be at least

80,000 divided by 30 = 2666 square mm. That would be obtained by 9

holes of 20mm diameter

Click to see a demonstration video of

these bellows in action

You can see how this double-acting bellows idea evolved in

this

forum topic |

Back to the Articles Index

This web site is copyright (C) Melvyn

Wright and individual contributors |